An interesting article published by Nikkei Asian Review’s Yuji Nitta has offered a rare look inside a little-known PlayStation plant located in Kisarazu, Japan, that has the ability to put together a new console every 30 seconds!

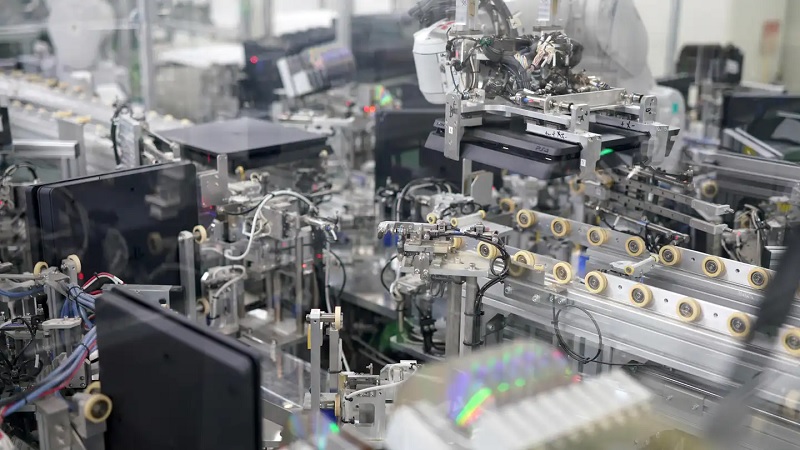

The 31.4 meter long production line was completed in 2018, and is almost entirely automated with just a few employees feeding motherboards to the line, and packaging consoles. Everything else is handled by robots supplied by Mitsubishi.

According to Nitta, 26 out of the 32 robots are dedicated to complex tasks like attaching wires and tapes to the consoles.

“Attaching the flexible flat cable – a tape-like electrical cord – requires one robot arm to hold up the cable and another to twist it,” wrote Nitta. “The cable then needs to be attached in a specific direction using just the right pressure, which may seem simple for a human but is an extremely complex maneuver for robot.”

Sony is known to keep its production processes a secret. This is the first time a member of the public was able to step inside what was previously off-limits. Nitta reported that some parts of the production line are even off-limits to Sony’s own employees!

“There’s probably no other site that can manipulate robots in this manner,” an engineer told Nikkei. “I created profitable production lines,” added Sony Global Manufacturing & Operations architect, Hiroyuki Kusakabe.

The plant’s production line undergoes regular improvements to keep manufacturing profitable even when console sales begin to slow down towards the end of the life cycle.

We highly encourage checking out the full graphic-rich article, which contains high-resolution images of the plant.

Let the PlayStation 5 production commence!

[Source: Nikkei Asian Review]